Address: No.53, South side of Dongqi Road, Donglai Village, Yangshe Town, Zhangjiagang City

phone:0512-58471920 / 58352807

Mobile phone:18901563608

Fax:0512-58471876 / 58352801

E-mail:sjf200865@126.com

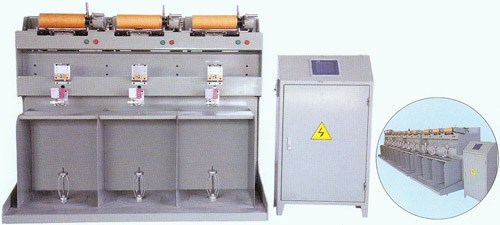

The company combines the market demand, digests and absorbs the technology of domestic and foreign winder, and develops a new generation of high-capacity, high-efficiency industrial winder GD500. The machine is controlled by microcomputer, and the whole machine is controlled by 12 spindles to achieve constant line speed winding. The utility model has the advantages of novel appearance, convenient operation cylinder, high degree of localization, large coiling capacity, and the like, and has the functions of self-stop winding diameter, setting of production process parameters and real-time status display of each spindle position.

This machine is mainly suitable for the pour of raw materials such as nylon and polyester. Through the small tube and large tube forming and feeding the straight boring machine, the advantages and performance of the straight boring machine can be fully utilized; or the jet and rapier looms can be supplied for large-scale weaving to reduce the shutdown process and improve the production efficiency. Great benefit.

The main technical parameters

| form | Independent multi-section connection |

| Number of spindles | 3 spindles / section × 4 (standard type) |

| Spindle distance(mm) | 500 |

| transfer method | Single spindle independent motor drive 0.55kw |

| Guide wire method | Blade alternate, moving stroke 250mm |

| Applicable bobbin | φ75×φ89×290(Can be customized according to user requirements) |

| Winding method | Winding head elastic clamping, center drive, pitch winding with T=84.5 |

| Winding speed | Constant line speed, 842m/min (can be set and modified according to yarn type) |

| Winding forming | Boundless, cylinder H=250mm |

| Winding diameter(mm) | φ250 |

| Feeding tension | Grid tensioner |

| Self-stop device | Light inductor |

| Winding pressure control | Back pressure constant pressure control |

| Total power of the whole machine(KW) | 6.6 |

| Overall size(L×W×H)(mm) | 7000×1155×1425 |